Business Process Excellence for Pharmaceuticals, Biotech and Medical Devices, The Brewery, London, April 2011 (1 of 2)

John Riddell and Elisabeth Goodman, RiverRhee Consulting1

This was the second of IQPC’s specialist conferences on this theme, and as last time2, many of those questioned by the authors were finding it of real value for learning about the specific application of Lean and Six Sigma in their environment.

The conference extended over 2 days, with pre-conference workshops covering a range of topics3. With the conference themes including strategy, change management, relevance to non-manufacturing environments, and innovation, it was obvious from the start that deploying Business Process Excellence was going to be about more than Lean and Six Sigma tools.

Business Process Excellence is not just about the (Lean and Six Sigma) tools

Martin Conroy, Director, Global Lean Sigma at Medtronic, kicked off the conference by reflecting about the pains encountered when moving to a continuous improvement culture and what can be done about them. He argued that Lean is an apparently simple concept, but one that can be difficult to ‘nail’: it’s not enough to have the tools, but they need to be used intelligently (with know-how), together and, especially, with the right mindset. He also emphasized that continuous improvement is neither a ‘bolt-on’ nor something to be done once (quickly) before moving onto the next initiative: it is something that requires careful planning and integration within the business.

Linking continuous improvement to organisational strategy

Many of the speakers referred to the importance of taking a holistic approach to implementing Lean and Six Sigma and of linking this to organisational goals. See for example Elisabeth Goodman’s4 presentation that included case studies on this. Tom Cochrane, Head of Security Operations and Process Development, Napp, described how their charter supports a continuous improvement culture although Lean and Six Sigma are never explicitly mentioned. Instead, they take a systems approach to the whole production process, and use statistical process control as an intrinsic continuous improvement tool across all disciplines, with cross-functional teams operating from the QA department.

Damian Morgan, Senior Executive, Accenture described how industry pressures and the Pharmaceutical Industry’s own responses were resulting in slowing growth and margin pressures. He suggested a consequential increased reliance on Operational Excellence (in the sense of Process Excellence) for winning. Pharmaceutical companies need to be agile, to be operationally excellent, and have differentiated capability. Indeed a cross sector study has shown that those who ‘win’ make investments in people and processes and, although they may look worse than their competitors who make draconian cuts in the short term, they recover more quickly and their recovery lasts longer (for more than 5 years).

Sauman Chakraborty, President and Global Head of Quality, HR & IT, described “Dr Reddy’s Way” which is a 4 strand strategic framework combining versions of EFQM’s Business Excellence Model, the Balanced Scorecard, Policy Deployment, and a Strategy and Tactics Logical Tree and underpinning everything that they do.

Top-down, middle-out or bottom-up implementation

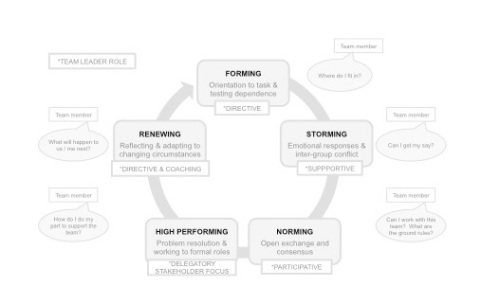

Elisabeth Goodman also explored the pros and cons of taking a top-down, middle-out, or bottom-up approach.

This was a theme that came up in the first panel discussion. Responses centred on “Yes, leadership can be sceptical” or “just don’t get it”, but can be brought round if they understand, or more importantly, tangibly see the benefits. The bottom-up approach can be used to generate examples that demonstrate value and approaches. Middle-out must not be forgotten, and here champions and change agents provide a key influence.

The theme also came up in the second panel discussion, when Karsten Benzing, Boehringer Ingelheim said that their most successful project were those driven top-down by leaders. A further thought was that a bottom-up approach only has a finite life as “you can only do something for so long without your boss’s approval”.

Engaging leadership: senior management need to be involved

It was suggested in the second panel discussion of Day 1 that there are two levels of leadership support – passive – “I’ll let you do this”, and active – getting involved and showing commitment.

Celia Banks’ (R&D and Medical BT CI Lead, Pfizer) initial work in Pfizer was as a contractor engaged to prove the benefit of a Continuous Improvement programme to a sceptical leadership (they were unsure how a “manufacturing programme” could be applied in R&D). Some pilot projects were carried out, ensuring that they tied in to a strategic imperative, and the necessity of top-down support identified. Celia also recommended the use of Nemawashi with senior management i.e. introduce ideas step-by-step (and involving them in developing), and not going to them with a packaged solution.

Engaging staff: it’s about improving people’s lives at work

The first panel discussion on day 1 included the theme of engagement of staff. Delegates and panellists discussed the importance of using simple language, giving recognition, and ensuring that people’s lives improve. The word “humility” was used in the context of recognising that managers “are non-value-adding” and that their role should be to ask questions and facilitate and look for their people to provide answers.

Chris Christodoulou, Head, Laboratory Compliance, MedImmune came back to this theme in his presentation when he described how Operational Excellence is introduced to new employees during induction, and yellow belt training is available to everyone, with a target of >80% take-up. There is an emphasis on communicating successes to show measurable result, and showcase projects including small yellow belt projects. All projects are expected to deliver tangible benefits.

The underlying message of his various case studies (management of consumables in the lab, analytical process simplification, 5S of the fridge, templates for writing up, and eliminating duplicate HPLC testing ) was to “do simple projects to make peoples’ lives easier and happier, and make things work better.”

The value of training everyone: organise training so that it is utilised immediately

The second panel were asked about the value of training everyone. Chris Christodoulou said that this would result in everyone talking the same language and plant seeds [i.e. it’s part of the culture change]. David Hampton, Rath & Strong, “controversially” pointed out that training itself is non-value adding and that green and black belt training needs to be integrated with a project and support.

Celia Banks described how specific training was devised for Continuous Improvement leads – on-demand, on-line, rather than as a block in a classroom.

Charles Aubrey, Vice President Performance Excellence, Anderson Pharmaceutical Packaging, echoed the approach of integrating training into application. Their programme was initiated through 4 days of training with the Leadership Team (to create understanding) then a pilot project was carried out in order to get buy-in. From there a comprehensive programme developed with the aim of everyone in the organisation having a role e.g. Yellow belts objective was to improve the way they work (they defined the 8th of Ohno’s wastes as that of the human mind).

The role of black belts

Martin Conroy was the first to raise the role of black belts in organisations. He referred to them as experts parachuted in “behind enemy lines” and described the challenges that they face the biggest one being the need for people to recognise that continuous improvement is not about these experts “doing things to or for you”.

A panel discussion later in the day came back to the role of black belts. It was generally thought that they should be full-time so they are more practised in the basics and have a wider set of tools, but there were mixed views on where their expertise should be applied. One panellist’s view was that black belts can be a “nuisance” e.g. in causing processes to be reworked unnecessarily e.g. Kanbans, to achieve standardisation across an organisation.

Using consultants: bring in someone to help kick-start programmes

There was agreement in the first panel discussion, that building internal capability is essential, but external involvement by consultants can bring in lessons learnt and play a role in mentoring senior management.

Panellists in the second discussion suggested that consultants were useful for transformational projects, although a further guarantee of the success of such projects was that they would necessarily involve senior leadership commitment.

Notes and further reading:

- RiverRhee Consulting enhances team effectiveness using process improvement, knowledge management and change management. Follow the links to find out more about RiverRhee Consulting and about Elisabeth Goodman and John Riddell

- Business Process Excellence for Pharmaceuticals, Biotech & Medical Devices – April 2010 – Key Themes http://wp.me/pAUbH-2u

- John Riddell and Elisabeth Goodman ran a workshop entitled: “Communities of practice and other knowledge management techniques to implement and sustain continuous improvement”. Please contact us if you would be interested in arranging a version of this workshop for you. http://slidesha.re/eoqKH5

- Elisabeth Goodman. “Sustaining Effective Continuous Improvement In An Organisation: A Holistic View”. Presented at Business Process Excellence for Pharmaceuticals, Biotech and Medical Devices, The Brewery, London, April 2011 http://slidesha.re/h2vVhN